CRANES, HOISTS, AND HANDLING DEVICES

The crane and hoist industry is concerned with both the floor-mounted and, more importantly, overhead transportation of loads within a three-dimensional work area. Cranes and related lifting equipment are an essential part of many production and assembly halls, ports, mines and railroad stations. Handling (components) are primarily used at the assembly site when ergonomic lifting solutions are required for the virtually weightless lifting of (individual) loads.

Although there are some very large global suppliers active in the segments mentioned above, the area of small to medium-sized companies and suppliers with a regional focus is still highly fragmented. As these companies are facing increasingly strong competition from East and Southeast Asia, they are likely to face greater pressure to consolidate in the future, to be able to position themselves strategically and effectively. However, many companies lack a coherent internationalization strategy.

In cooperation with Aquin’s Senior Advisor Wolfgang Schorre, who has more than 40 years of industry expertise and leadership experience, we are able to jointly develop concepts to ensure a successful M&A process on both the sell and buy side.

CRANES, HOISTS, AND HANDLING DEVICES – FACTS, FIGURES, BACKGROUND

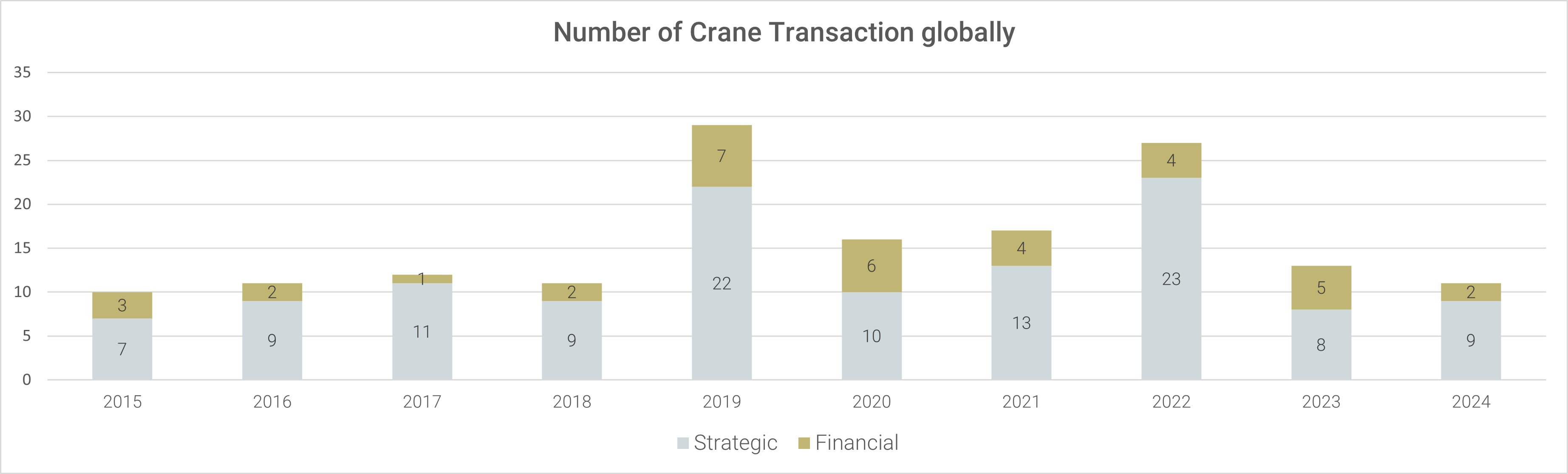

Companies in the crane and lifting equipment industry are largely medium-sized and family-owned. Against this backdrop, the increasing internationalization of competition and the high level of M&A activity in the market – particularly internationally – have a significant impact. This trend points to rising consolidation pressure, driven in part by larger players such as Columbus McKinnon, Konecranes, or Piab, who benefit from easier access to capital. At the same time, ongoing digitalization is reshaping the requirements for mid-sized manufacturers. Smart cranes with IoT integration, data analytics, and remote-control capabilities are driving technological change, with further intensification expected in the areas of automation and occupational safety. A strategic approach for medium-sized companies is to expand their value creation horizontally or vertically and differentiate themselves through quality, local service, or a specialized niche position.

Source: Aquin Research, Capital IQ

The graphic shows the number of global crane, lifting equipment, and handling transactions since 2015. On the buyer side, a distinction is made between “pure” strategists, strategists backed by financial investors, and “pure” financial investors. Although the crane and lifting equipment industry is already highly consolidated, it continues to be shaken by larger deals in addition to numerous mid-market transactions — most recently through the acquisition of Kito Crosby by Columbus McKinnon and a total of six transactions by Konecranes. The industry is shaped not only by increasing internationalization but also by the growing influence of digital technologies: smart cranes with IoT integration, data analytics, and remote-control capabilities are gaining importance, and further intensification — particularly in automation and occupational safety — is expected. These developments present ongoing challenges for medium-sized companies while simultaneously acting as M&A drivers for future transactions.

Source: Aquin Research, Capital IQ

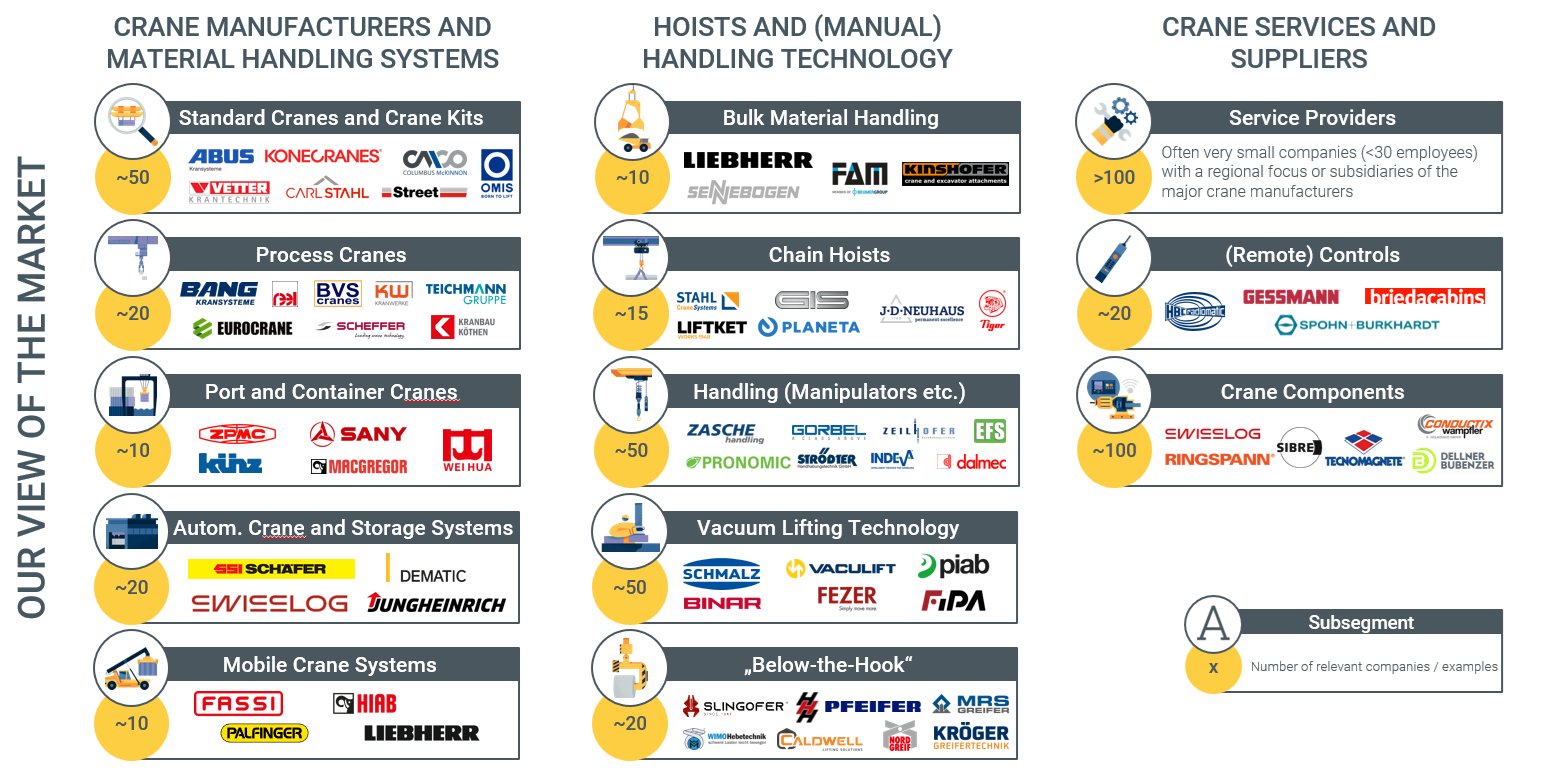

SUB INDUSTRIES

In production plants and processes, standard and process cranes, (electric) hoists and handling technology are essential components for solving the internal material flow and for designing a modern and ergonomic workplace. Furthermore, a wide range of applications can be found for automated and mobile crane solutions at handling sites and for lifting a wide variety of goods. Therefore, Aquin covers the following segments:

|

Standard cranes and crane kits

„In manufacturing operations, standard cranes are an ideal combination of production efficiency and profitability in all manufacturing areas.” |

|

Process Cranes

“Automated or manually-operated process cranes are designed for specific applications and are suitable for adverse working environments.” |

|

Port- and Container Cranes

“Crane systems specifically designed for (extensive) handling areas for transporting goods on ships or by rail.” |

|

Automated Cranes and Warehouse Systems

“(Fully automated) warehouse systems that map the internal flow of materials with regard to transfer, storage and retrieval.” |

| Mobile Crane Systems

„Mobile crane systems offer the greatest possible flexibility to operate in a space-efficient manner, whether on land, in ports or at sea.” |

| Bulk Material Handling

“Gripper, crane and material handling solutions for transporting loose material such as sand, gravel or crushed stone.” |

|

Chain Hoists

“Chain hoists provide an efficient (but not weightless) method of lifting and lowering free-moving loads.” |

|

Handling (Manipulators, Balancers, etc.) and Ergonomics “Electric or pneumatic ergonomic lifting solutions that allow the operator to lift (individual) loads in a nearly weightless manner.” |

|

Vacuum lifting

“Vacuum lifters are often used for lifting standardized or easy-to-lift loads such as glass, sheet metal or wood.” |

|

„Below-the-Hook“

„Various gripper and hook solutions provide maximum handling flexibility, including heavy-duty and automated crane systems.” |

| Service Companies

“Inspection, preventive (remote) maintenance or quick supply of spare parts – service companies in the crane sector cover a wide range of services.” |

| (Remote) controls

“Ease of us is key to broader acceptance and user base – this applies from small control units all the way through to complex, ergonomic control (management) stations.” |

| Crane components: Drive technology, rail systems, sensors, electronics, etc.

“Motors, gears, control cables, sensors, rail systems and more are the foundation of any reliable crane or handling system.” |

PUBLICATIONS

05.2022

- A conversation with Jenny Eagle, Thomas Grauvogl and Wolfgang Schorre on the subject of cranes and hoists.